Using genuine manufacturer parts for collision and frame repairs ensures superior quality, precise engineering, and specific design for your vehicle. They offer perfect fitment, save time/costs, maintain safety, preserve structural integrity, and come with factory warranties. These parts are rigorously tested, reliable in diverse road conditions, and ideal for professional body shop services.

When it comes to collision and frame repairs, using genuine manufacturer parts is paramount. These original equipment components ensure superior performance, longevity, and safety compared to aftermarket alternatives. This article delves into the significance of genuine manufacturer parts, highlighting their benefits for collision repairs and frame straightening. Learn how to maintain quality standards during assembly and why this choice is a game-changer for auto body shops, ultimately enhancing repair outcomes.

- Understanding the Importance of Genuine Manufacturer Parts

- Benefits of Using Original Equipment for Collision Repairs

- How to Ensure Quality During Frame Straightening and Assembly

Understanding the Importance of Genuine Manufacturer Parts

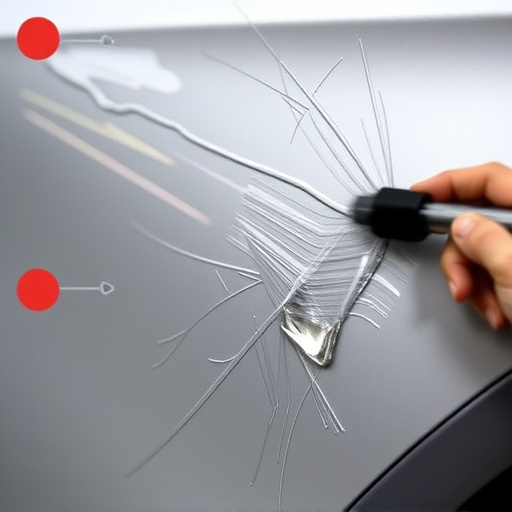

Using genuine manufacturer parts is paramount when it comes to collision and frame repairs. These original components are designed and tested specifically for your vehicle make and model, ensuring they meet the highest standards of quality and performance. They perfectly align with your vehicle’s design, offering superior fitment that saves time and labour costs for the body shop while maintaining safety and structural integrity.

Choosing genuine parts also guarantees compatibility with existing factory warranties and provides peace of mind. Unlike aftermarket parts which may lack rigorous testing or precise engineering, genuine manufacturer parts offer a reliable solution for car dent repair and other frame-related damages. They are engineered to withstand various road conditions and driving styles, ensuring your vehicle’s structural integrity remains intact after repairs are completed by professional body shop services.

Benefits of Using Original Equipment for Collision Repairs

Using genuine manufacturer parts for collision and frame repairs offers numerous advantages that can significantly impact the quality and longevity of your vehicle’s restoration. These original equipment parts are designed specifically to fit your make and model, ensuring precise alignment and seamless integration into the existing structure. This precision is crucial in maintaining the structural integrity of the vehicle, which is especially important for safety-related components like frames and body panels.

Moreover, genuine manufacturer parts often come with extensive quality control measures and testing protocols, guaranteeing superior performance and durability compared to aftermarket alternatives. In the realm of classic car restoration or modern auto body services, where meticulous craftsmanship is paramount, relying on these authentic parts can preserve the vehicle’s original characteristics and ensure it meets the highest standards. This attention to detail not only enhances the overall aesthetics but also guarantees reliable long-term functionality, making them an ideal choice for anyone seeking top-notch car paint services or comprehensive auto body repairs.

How to Ensure Quality During Frame Straightening and Assembly

When it comes to collision and frame repairs, ensuring quality is paramount to achieving safe and reliable results. Utilizing genuine manufacturer parts is a critical step in this process. These parts are designed specifically for your vehicle’s make and model, offering an exact fit and superior performance compared to aftermarket alternatives. By choosing genuine parts, you gain access to the same high-quality materials and precise engineering standards that the original manufacturer used.

During frame straightening and assembly, meticulous attention to detail is required. Using genuine manufacturer parts ensures consistency with the vehicle’s original design and specifications. This precision is vital for maintaining structural integrity and ensuring proper alignment after repairs. It also facilitates seamless integration of new and repaired components, enhancing the overall quality of collision repair services and resulting in top-notch automotive body work.

When it comes to collision and frame repairs, using genuine manufacturer parts is paramount. These original equipment pieces not only ensure superior quality and performance but also maintain the integrity of the vehicle’s design and safety features. By choosing genuine parts, repair shops can deliver top-notch results that stand the test of time, ensuring customer satisfaction and peace of mind on the road.