Understanding unique part numbers and advanced technologies like barcodes, QR codes, and RFID tags ensures authenticity of genuine manufacturer parts. Physically inspect material composition, identifiers, and construction quality for subtleties distinguishing genuine parts from counterfeits. Utilize official documentation and warranty info to verify origin, compatibility, and performance standards, preventing the use of counterfeit components critical for vehicle safety and reliability.

When it comes to maintaining your vehicle, ensuring the authenticity of genuine manufacturer parts is paramount. This guide will walk you through effective strategies to verify their legitimacy. We’ll explore identification methods used by manufacturers, key physical characteristics to look for, and how to leverage official documentation and warranty information. By following these steps, you can confidently choose authentic parts, ensuring optimal performance and peace of mind.

- Understanding Manufacturer Part Identification Methods

- Examining Physical Characteristics for Authenticity

- Leveraging Official Documentation and Warranty Information

Understanding Manufacturer Part Identification Methods

In the quest for genuine manufacturer parts, understanding the identification methods employed by automotive manufacturers is paramount. These methods ensure that the parts acquired match the exact specifications and quality standards set by the original equipment maker. One common approach involves utilizing unique part numbers, which serve as digital fingerprints, identifying each component precisely. This system allows for easy cross-referencing with the manufacturer’s databases, confirming the authenticity of the part.

Additionally, manufacturers often employ advanced technologies like barcodes, QR codes, or RFID tags, integrated into the packaging or directly on the part itself. These digital markers facilitate quick verification processes, making it easier to distinguish genuine parts from counterfeits. Whether for an auto glass replacement, vehicle dent repair, or classic car restoration, employing these identification techniques ensures that only original and high-quality manufacturer parts are utilized.

Examining Physical Characteristics for Authenticity

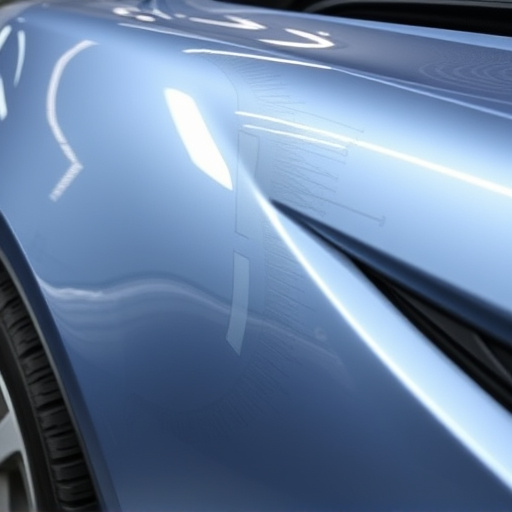

When examining genuine manufacturer parts, paying close attention to physical characteristics can be a powerful tool for authenticity verification. Look for subtle differences in material composition, such as the texture and color of plastic or metal components. Genuine parts often have unique identifiers, serial numbers, or logos that are precisely etched or molded into the item, ensuring their integrity. These markings may not be easily visible to the naked eye but can be spotted with careful inspection using appropriate lighting or magnifying tools.

Additionally, consider the overall construction quality. Original equipment manufacturer (OEM) parts typically adhere to stringent quality control measures, resulting in precise dimensions and seamless assembly. Compare these aspects against known genuine examples from reputable sources, focusing on details like edge alignment, fitment, and finish. This meticulous examination can help you identify potential counterfeits that might exhibit inconsistencies or inferior craftsmanship, especially when scrutinizing auto glass repair, auto body services, or dent removal components.

Leveraging Official Documentation and Warranty Information

When verifying the authenticity of genuine manufacturer parts, official documentation and warranty information are invaluable tools. Many reputable manufacturers provide detailed specifications, serial numbers, and part numbers that can be cross-referenced with legitimate suppliers. These documents not only guarantee the part’s origin but also its compatibility and performance standards. By comparing the information on these papers to the actual part, you can ensure it is genuine and of high quality, which is especially crucial for critical components in vehicles.

For fleet repair services or comprehensive car damage repair involving intricate car bodywork services, having access to such documentation is essential. It allows technicians to confirm that each replacement part meets the original manufacturer’s standards, ensuring the safety and reliability of the vehicle. Moreover, this process helps prevent the use of counterfeit parts, which can lead to long-term performance issues and costly repairs.

When purchasing replacement parts, verifying their authenticity is crucial to ensure quality and compatibility. By understanding the manufacturer’s identification methods, examining physical characteristics, and referencing official documentation, you can confidently choose genuine manufacturer parts for reliable performance and peace of mind. Stay vigilant against counterfeits and invest in the original equipment that meets your vehicle’s exacting standards.